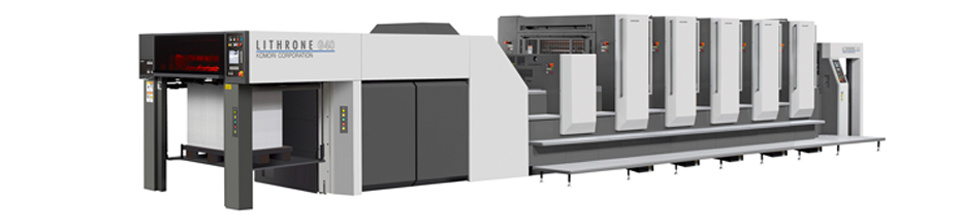

Komori Lithrone S 26/S 29

<b>FEATURES</b>

26"/29"Offset Printing Press

<b>Automation for the World's Shortest Setup</b>

The Lithrone S26/S29 features extensive automation for the world's shortest make-ready thanks to the incorporation of Komori's most advanced technologies.

These range from the new Full-APC (the first fully automatic plate-changing system specifically designed for a half-size press) that eliminates the need for a tail bend on the plate and is capable of changing four plates in just two minutes 30 seconds, to completely automatic wash-up of the blanket and impression cylinders and inking rollers.

Unique Komori expertise and technologies ensure seamless interlocked operation of these automatic systems to achieve the shortest make-ready available anywhere.

<b>The Ultimate Short-Run Machine</b>

Short-run capability and quick turnaround performance remain the persistent needs of the printing industry. Moreover, the wider use of on-demand presses and increased price competition has made the requirements for sheet-fed offset presses very rigorous.

In addition to exceptionally short make-ready, the Lithrone S26/S29 offers a high-speed (12,000sph) initial printing function, a maximum printing speed of 16,000sph with ultra-stable print quality and a high-speed pre-inking system.

These functions work together to reduce the time, from the end of one 200-page job to the start of the next job, by 50% - to a mere six minutes. This unprecedented job changeover time is a powerful instrument for handling short-run work profitably.

In fact, the Lithrone S26/S29 has the unheard-of capacity to finish 10 jobs of 200 pages each in just one hour. (Figures show Komori measurements under specific conditions. No warranty is implied

<b>Extending the Lithrone Tradition with Evolved Print Quality</b>

The major advantages of the Lithrone S26/S29 include high print quality, high reproducibility, superior inking and distribution and colour brilliance along with high productivity. The printing units are at the core of this quality.

They incorporate an optimised roller configuration derived from a computer analysis to specify the ideal model for maintaining the optimum balance of ink and water, ensuring sufficient ink retention and attaining high print quality.

In addition, the Lithrone S26/S29 printing units are equipped with the Komorimatic dampening system, which provides a consistent supply of dampening solution directly to the plate and also enables high-quality non-alcohol printing with the minimum necessary amount of water. The printing units also exhibit very high rigidity due to micron-order machine accuracy. The essence of the Komori pursuit of high print quality.

<b>Advanced Operation Console for Digital Control</b>

Equipped with dual large-screen touch-panels, the new operation console allows nearly all press adjustments to be made easily by remote control.

The operation console can be configured with the CIP4/JDF-compatible K-Station (optional) and the KHS-AI (Advanced Interface)(optional). This centralised control offers a real time view of press operating conditions with external data. The improved operating environment not only facilitates management streamlining but also reduces the operator's task load.

Combining these capabilities with the optional PDC-SII Print Density Control-Spectrophotometer and K-ColourProfiler II enables numeric control for colour matching printed items and smooth implementation of advanced colour management, a major step toward printing standardisation. The Komori command centre is ready to evolve with future digital technologies.

| Model | Number of Colours | Max. Sheet Size (mm) | Max. Printing Area (mm) | Plate Size (mm) | Feeder Pile Height (mm) | Delivery Pile Height (mm) |

| LITHRONE S 26 | 2,4-8 | 480x660 | 470x650 | 560x670 | 800 | 900 |

| LITHRONE S 29 | 2,4-8 | 530x750 | 520x740 | 605x760 | 800 | 900 |

Latest Machines

|

1996 Komori Lithrone 440 |

1996 Komori Lithrone 440 72x103 4 color B1 |

|

2005 Komori Lithrone S540+C |

2005 Model Komori Lithrone S540 5 five colors + Coating 72x103 B1 |